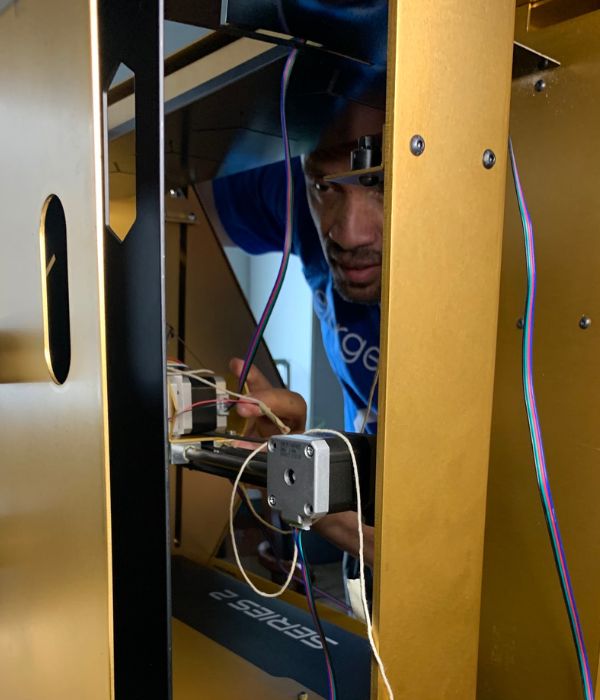

At Morningbird Space, we leverage groundbreaking additive manufacturing technologies to propel your projects beyond the earth’s atmosphere. Our AppBot 3D printers bring your most complex designs to life, ensuring precision and efficiency in every creation.

AppBot

Facing challenges in obtaining specialized parts for space exploration? Traditional manufacturing can be slow and costly, often not meeting the unique demands of space-grade components. With the AppBot 3D printers, these issues are a thing of the past. Our technology is designed to produce high-quality, multi-material objects ready for the harsh conditions of space, simplifying the manufacturing process and slashing costs. Whether you’re building a satellite or designing a new habitat on Mars, our printers are tailored to support ambitious projects with unmatched agility and precision.

Print with up to six different materials simultaneously, including metals, plastics, and composites, for complex, functional components.

Achieve exceptional detail and accuracy with resolutions finer than what traditional manufacturing methods can offer.

From small bespoke pieces to larger structures, scale your production as needed without significant additional costs.

Printing – Your designs are brought to life using our advanced AppBot 3D printers.

Learn how our clients are leveraging the AppBot 3D printers to revolutionize additive manufacturing processes. These testimonials highlight the transformative effects of our technology on their design capabilities and production efficiency.

I am ecstatic about the potential of the AppBot from Morningbird Space. Morningbird’s commitment to pushing the boundaries of additive manufacturing aligns perfectly with our vision to support space communities and advance humanity’s reach into the cosmos.

Being involved in the creation and development of the AppBot has been one of the most rewarding experiences of my career. We see this as a platform for innovation, ready to empower young minds toward the outer edges of creativity.

The ability to 3D print fully functional electronic devices will open up whole new avenues in science. This is incredibly exciting for us: we are one step closer to Star Trek’s replicators.

Additive manufacturing allows for rapid prototyping, customization, and complex geometries not possible with traditional manufacturing, reducing costs and improving efficiency in space missions.

Our printers are capable of handling a variety of materials, including advanced composites, high-strength polymers, and metals.

Yes, our printers are designed to produce parts that meet the stringent quality standards required for space missions.

This structured approach ensures that the content not only aligns with Morningbird Space’s brand voice but also effectively communicates the unique benefits and capabilities of their additive manufacturing technology to prospective clients.

Pioneering the future of space technology through advanced additive manufacturing.