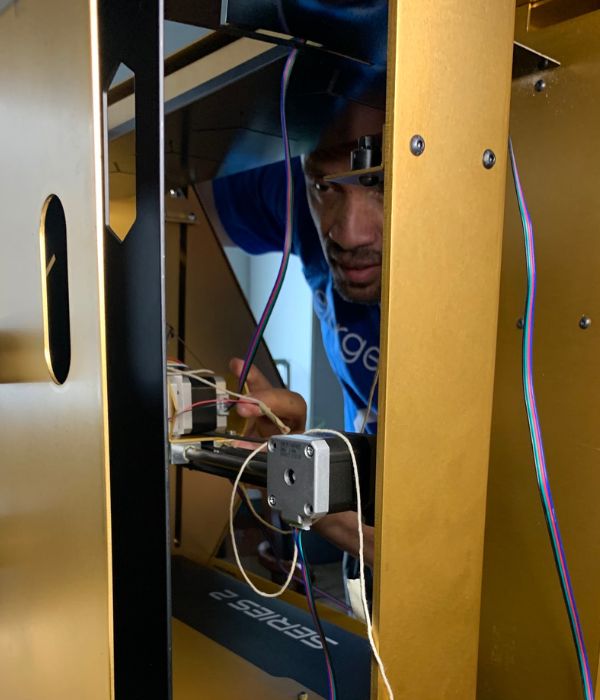

At Morningbird Space, we are driven by innovation and the pursuit of cutting-edge technology. The eforge Series 3.1, our latest innovation, is now available for pre-order at a special introductory price. This advanced printer, supported by NASA, is designed to revolutionize your 3D printing experience, allowing you to create fully functional electronic devices with unparalleled precision and versatility. Embrace the future of 3D printing with the eforge Series 3.1.

eforge

Series 3.1

At Morningbird Space, we believe in empowering innovators and creators. The eforge Series 3.1 is more than just a 3D printer; it’s a gateway to unlimited potential. With its state-of-the-art features and robust construction, the eforge Series 3.1 is designed to meet the demands of professionals across various industries, from aerospace to education. Whether you’re developing intricate prototypes, manufacturing complex components, or pushing the boundaries of research and development, the eforge Series 3.1 delivers precision, reliability, and versatility like never before.

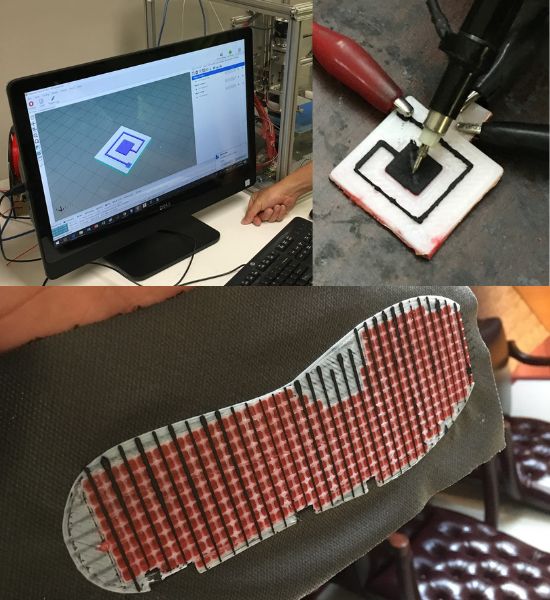

The eforge Series 3.1 excels in 3D printing with its advanced electronic printing capabilities, integrating the fabrication of electronic components like circuit boards and sensors directly into 3D projects. This printer combines a specialized extruder and a versatile 6-material EA filament pack handle our proprietary electronics materials filaments as well as standard thermoplastics seamlessly. Enhanced by the Electronic Alchemy Design Cauldron slicer, the eforge Series 3.1 ensures precise, contamination-free prints and optimizes electronic circuit layouts within 3D structures. This enables the creation of complex, integrated products that combine mechanical and electronic functions, opening new possibilities in customized manufacturing and smart system development.

With a 6-material EA filament pack and a 6-tool changer, the eforge Series 3.1 allows you to print a wide range of materials, including electronic parts.

The Direct Drive E3D V6 Titan Aero extruder and heated bed provide consistent and high-quality prints, while the robust frame construction ensures stability and accuracy.

The Duet Main 6hc controller and SD card file transfer make the printing process seamless and straightforward. Our intuitive slicer software, Electronic Alchemy Design Cauldron, simplifies design and execution.

Achieve remarkable efficiency with the eforge Series 3.1’s capability to print at speeds of up to 120 mm/s. This high-speed performance does not compromise print quality, making it ideal for both rapid prototyping and detailed manufacturing tasks.

With a sturdy 9.5 mm frame construction and a heated bed that reaches up to 110°C, the eforge Series 3.1 ensures every print is of the highest quality. The precise engineering behind its design guarantees reliable and repeatable results.

Dive into the technical specifications below to see how the eforge Series 3.1 can transform your projects and elevate your creative capabilities.

150x150x100

340x360x370

6-material EA filament pack (2.85 mm)

Direct Drive E3d V6 titan Aero

6 independent total tools

Heated bed (110C max)

Magnetic PEI Sheet

Duet Main 6hc v1.02 with 2x expansion

24V 240W with 120v main voltage

SD card on screen panel

120 mm/s

9.5 mm

Bed on Z axis, gantry on xy-axis

Reprap

IEC 2 m

Electronic Alchemy Design Cauldron

Don’t miss the opportunity to revolutionize your 3D printing projects with the eforge Series 3.1. Available for pre-order at a limited-time introductory price. Click below to secure your eforge Series 3.1 today*.

Learn how our clients are leveraging the eforge 3D printer to revolutionize additive manufacturing processes. These testimonials highlight the transformative effects of our technology on their design capabilities and production efficiency.

I am ecstatic about the potential of the eforge series from Morningbird Space. Morningbird’s commitment to pushing the boundaries of additive manufacturing aligns perfectly with our vision to support space communities and advance humanity’s reach into the cosmos.

Being involved in the creation and development of the eforge has been one of the most rewarding experiences of my career. We see this as a platform for innovation, ready to empower young minds toward the outer edges of creativity.

The ability to 3D print fully functional electronic devices will open up whole new avenues in science. This is incredibly exciting for us: we are one step closer to Star Trek’s replicators.

The eforge Series 3.1 can handle a diverse array of materials thanks to its 6-material EA filament pack, which is compatible with filaments of 2.85 mm diameter. This allows for high versatility in printing different types of electronic and mechanical components.

The eforge Series 3.1 has a build volume of 150x150x100 mm, providing ample space for most small to medium-sized projects that require precision and detail.

The heated bed of the eforge Series 3.1 can reach a maximum temperature of 110°C, ensuring excellent adhesion and quality for a variety of materials.

Yes, the eforge Series 3.1 is designed with both beginners and experienced users in mind. It features a user-friendly interface with an SD card on-screen panel for easy file transfer and operation. Additionally, it uses the Electronic Alchemy Design Cauldron slicer software, which simplifies the process of preparing your models for printing.

The eforge Series 3.1 offers a maximum printing speed of 120 mm/s, allowing for rapid production without sacrificing the quality of the output.

NASA supported the development of the eforge through Phase I, II, and III STTR and SBIR contracts. This support underscores the quality and viability of the technology.

The printer dimensions are 340x360x370 mm, and weighs less than 50 lbs making it a compact yet powerful device suitable for various settings, from classrooms to professional labs.